- Home

- About Us

-

Products

Lithium

Roller press CCD detection system

Roller Slitting Machine CCD Detection System/Labeling Machine

Pole slice CCD detection system

Independent wide CCD re-inspection machine

Tab forming equipment CCD system

Power battery winding machine CCD detection system

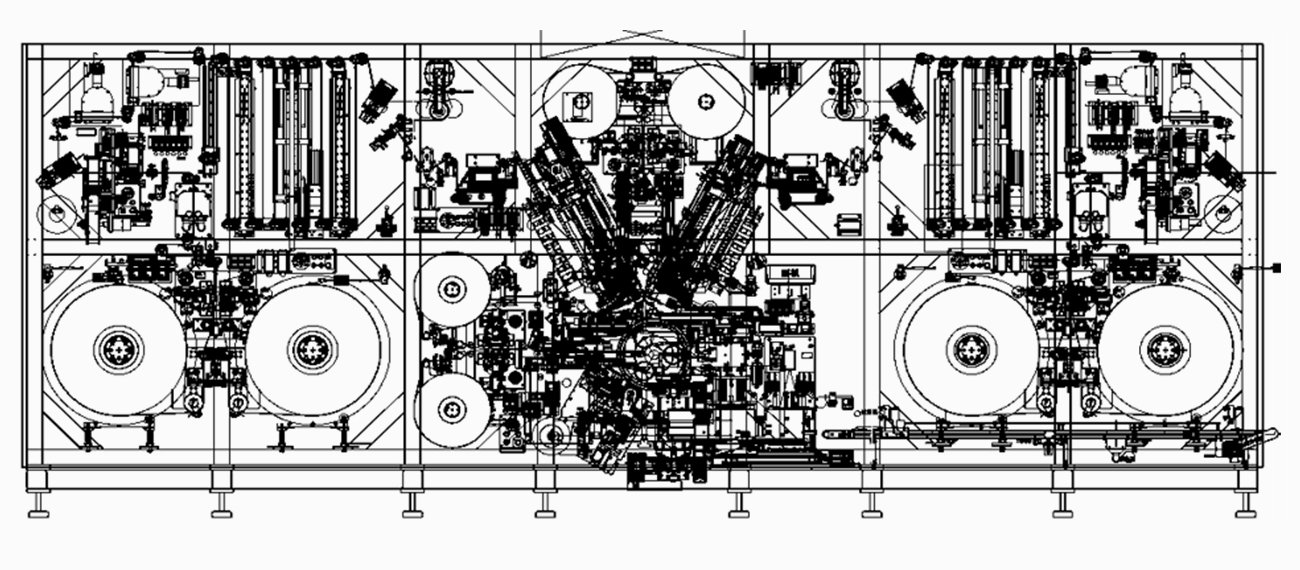

Cutting and stacking machine CCD detection system

Power Bare Cell Appearance Inspection Machine

Power battery casing equipment/pre-spot welding

Power battery top cover welding inspection machine

Power battery sealing nail detection system

Inspection of the front six sides of the blue film of the power battery pack

Power battery aluminum shell, blue film appearance inspection machine

Finished battery appearance inspection machine

Power battery connector welding detection system

Blade Battery Measurement Dimension Measuring Machine

Power battery module Busbar testing machine

Power battery module size detection

Small power battery automatic FT test and air tightness testing machine

Copper foil appearance inspection

Aluminum foil appearance inspection

Diaphragm appearance inspection

Aluminum plastic film appearance inspection

- Technology

- R&D

- News

- Recruitment

- Contact Us